SPECIFICATION

INJA ROBOTICS & AUTOMATION Air Leak Test Machines with dry as well as dry & water immersion method to check the porosity of Cylinder Block, Cylinder Head, Gear Housing, Clutch Housing, Oil coolers, high pressure gas cylinder, intake/exhaust manifold, engine assembly etc. with high pressure air leak test through microprocessor based pressure drop method with highest resolution to meet international standards.

Water dip machine has built in facility of water immersion for further analysis of leakage area which can be observed In illuminated water tank.

The procedure is to load the component on fixture, clamp and plug the component in position. Air will be pressurized in to the component till the pressure reaches a preset value, stabilise the air inside the component and checked for leakage through a pressure drop/flow sensor and the result is displayed on Leak Testing Instrument. If the component is rejected, it is immersed into the emulsion tank where the area of leakage is observed visually. In case of OK component punching will be done & depressurization, de-plugging followed by de-clamping takes place.

Drilling & Tapping Machines

SPECIFICATION

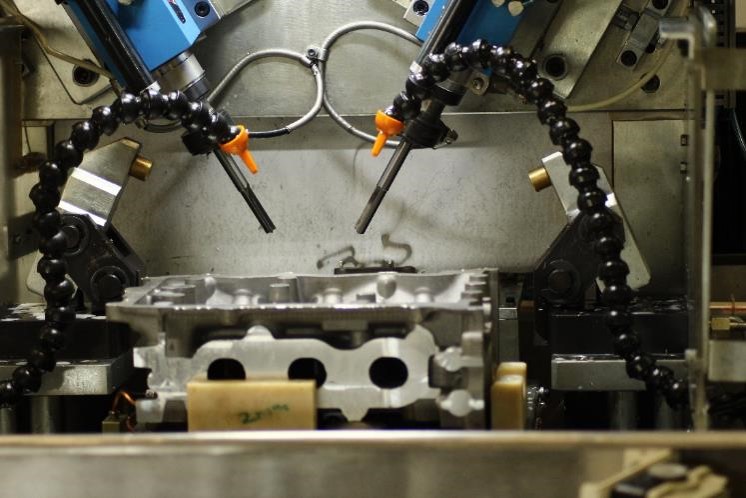

We manufacture and supply a quality range of Multi Spindle Drill Machine that is manufactured using latest technology and quality assured mild steel. Easy to install and operate, these machines provide accurate & precision drilling operations.

For the purpose of providing maximum satisfaction to our clients, we use the finest raw materials and modern machinery that are available. Owing to this and its market leading pricing, the Multi Spindle Drilling Machines have provided and it has known to be one of the primary choices. In addition, its superior sturdiness and unmatched resistance to corrosion, gives the product a longer service life.

Special Purpose Machine

SPECIFICATION

We have facilities to Design, Manufacture & Integrate Special Purpose Machines (SPMs).These SPMs were used at various applications like Punching, Weight checking, Laser marking & Screw driving etc. Our SPMs are also used for EOL Quality checking, Endurance testing.

Assembly Line Automation

SPECIFICATION

Various assembly operations like fitting, fastening, torquing, sealing, gasketting, setting can be automated to ensure high quality, no errors, and thoughput. Thereafter, the post assembly and in-procss verification (IPV) tests for assemblies are also automated to have 100% process control, high repeatability & reproducibility. These are coupled with technologies like SCADA, RFID tags and laser marking, enable high flexibility and traceability.

Material Handling

SPECIFICATION

Conveyors system with belt conveyor, roller conveyor with power feed robotic pick and place, loading and unloading. rotary feeding arrangement with cam type indexor and servo control indexor.

Performance / Endurance / Durability Test SPM

SPECIFICATION

Conveyors system with belt conveyor, roller conveyor with power feed robotic pick and place, loading and unloading. rotary feeding arrangement with cam type indexor and servo control indexor.